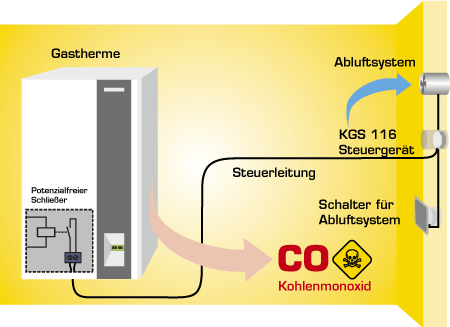

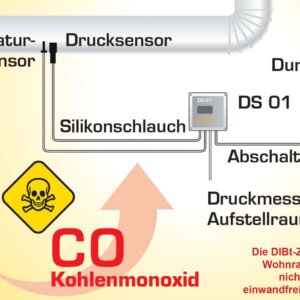

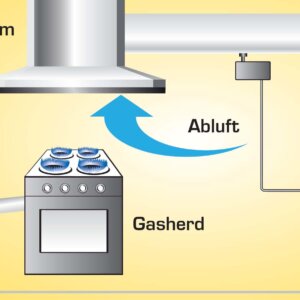

Exhaust air systems, such as a bathroom ventilator, create a negative pressure in the room unless sufficient air can flow in. As soon as a room-air dependent combustion appliance (e.g. gas boiler) is in the room, dangerous exhaust gases can be extracted from it and spread in the room. By using the KGS 116 cable exhaust air control unit, the exhaust air system can only be used when the combustion system (e.g. gas boiler) is switched off. The control line is connected to the control unit and to the gas boiler.

Ideal for retrofitting to an already installed 2-wire control line! The KGS 116 can only interrogate normally open contacts. A normally open contact is closed when the gas boiler is ignited.

Why don't I just use a relay?

From a purely technical point of view, a simple relay would be sufficient, but with the KGS 116 everything is already prepared ready for connection and protects the contact of the gas boiler with low control voltage. For safety, a cable breakage protection is also built in.

Performance features

- Cable breakage protection

- Terminal connections control unit

- Relay contact 16 A changeover contact (potential-free)

Scope of delivery

- Control unit

- Control cable 4 m

- Mounting material

The KGS 116 control unit is connected with a cable to the potential-free contact (NO contact) of the gas boiler. As soon as combustion starts, the exhaust air system (e.g. bathroom fan) is switched off. The control unit can be surface-mounted or flush-mounted in a distribution box, switch or socket with a minimum diameter of 60 mm. The side fixing lugs on the control unit can be broken away if required.

Technical data

| Operating voltage: | 230 V AC / 50 Hz |

| Switching capacity (max.) | 3500 VA (2300 W) / 16 A (10 A) |

| Control voltage: | 18 V |

| Control cable, extendable: | 4 m long (special length on request) |

| Functional area: | -15° C / +40° C |

| Protection class: | IP 20 |

| Control unit (HxWxD): | 51 x 51 x 26 mm |

WEEE NO.: EN91394868

Reviews

There are no reviews yet