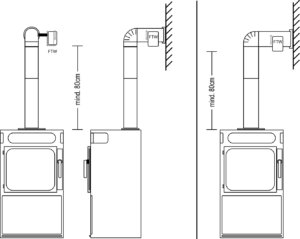

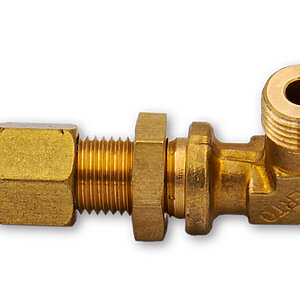

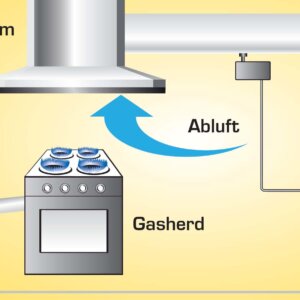

Der Cetrotec Abgastemperaturwächter Typ 519 mit 40°C Schaltpunkt ist vom TÜV bauartgeprüft, zugelassen für den Einsatz in Wärme erzeugenden Anlagen und wird mit einem Flansch an einem freien Stück Ofenrohr mit mind. 120 mm Durchmesser montiert.

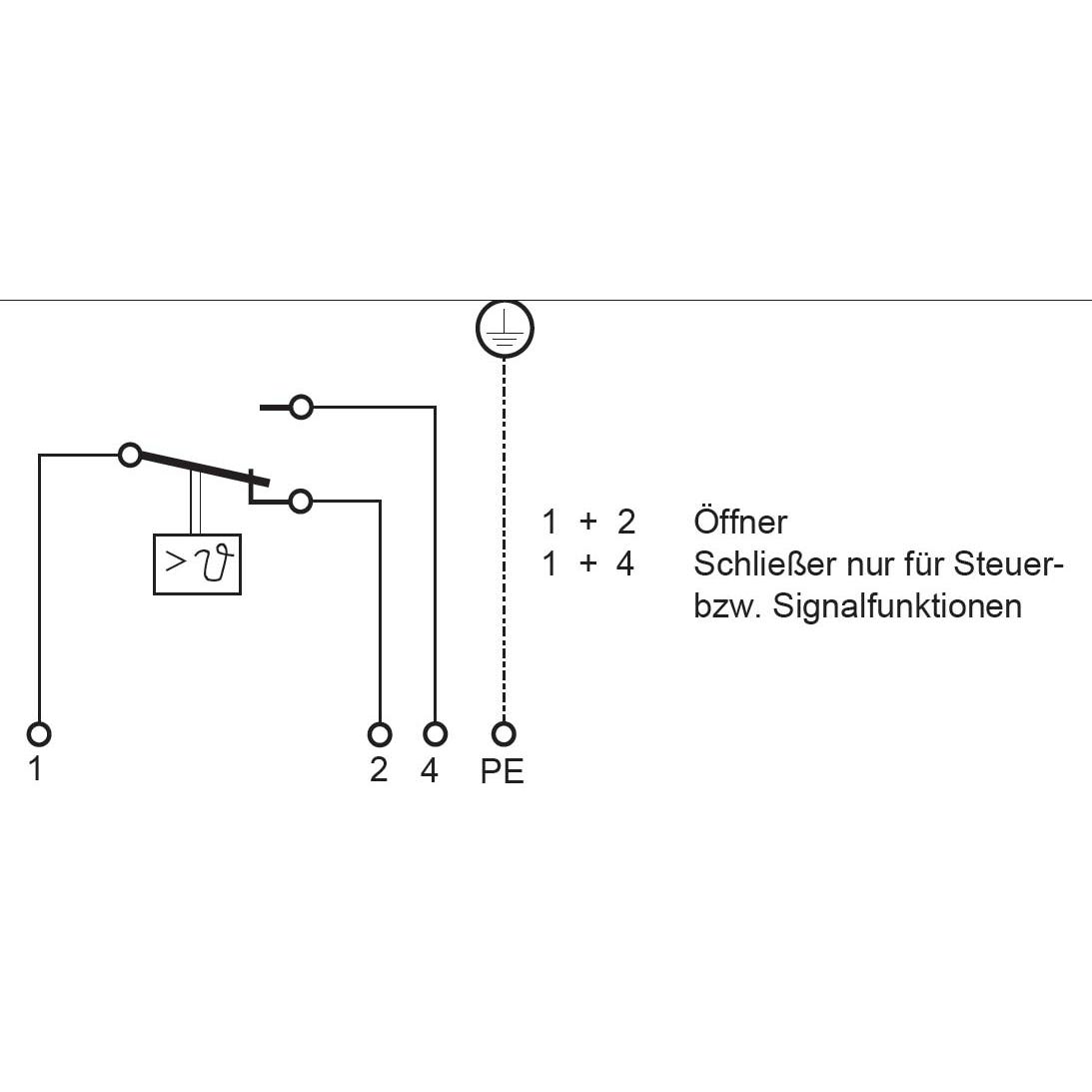

Sein Öffnerkontakt kann Leistung schalten, sein Schließerkontakt ist nur für Steueraufgaben vorgesehen, daher eignet er sich technisch, um bei kaltem Ofen eine Abluftsteuerung zu überbrücken oder wird leicht modifiziert als Steuergerät für unsere Kabel-Abluftsteuerungen eingesetzt.

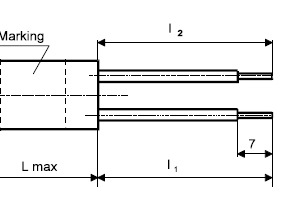

Der Rauchgasthermostat wird zur Überwachung der Abgastemperatur im Rauchrohr von wärmeerzeugenden Anlagen verwendet. Der Fühler des ATW besteht aus einem Metallrohr und einem darin angeordneten Metallstab mit unterschiedlichem Ausdehnungskoeffizienten, die bei Temperaturänderung eine Längendifferenz ergeben. Diese wirkt auf einen Präzisionsmikroschalter der oberhalb einer festeingestellten Grenztemperatur den Stromkreis unterbricht. Nach der Absenkung der Temperatur am Fühler um ca. 15 K unter den Schaltpunkt schaltet der Mikroschalter zurück und der Stromkreis wird wieder geschlossen. Hinweis: Achten Sie bei der Montage des Fühlers darauf, daß dieser nicht geknickt oder beschädigt wird.

WEEE-NR.: 91394868

Bewertungen

Es gibt noch keine Rezensionen