Do you have an account?

Log in, so that checkout is faster.

Availability for pickups could not be loaded

Item number: 300941

Delivery time: 2-3 working days

View full details

The compact mini float switches made of V4A stainless steel are ideal for applications with particularly aggressive or chlorinated liquids – for example, in chlorinated pool water, salt water, or weak chemical alkalis. Compared to V2A, V4A offers even greater corrosion resistance thanks to the addition of molybdenum and titanium. This makes the float switch suitable for use in environments where V2A reaches its limits.

The shaft of the float switch is milled and turned from solid V4A stainless steel, making it extremely stable – even under constant stress. The float body is made of thin, also rust-proof V4A sheet metal. Inside, a high-quality reed contact from Meder, which is watertightly cast into the shaft and firmly soldered, ensures permanently reliable signal transmission.

Combined with low switching power – less than 5 volts and 1 milliampere – the float switch achieves a service life of up to one trillion switching cycles. This means no mechanical wear, no maintenance, and no failures. Once installed, the switch operates precisely and reliably over the long term – even in confined spaces.

The float switch is equipped as standard with a 2.5-meter-long LiYY/PVC cable. According to the manufacturer, this cable is temporarily waterproof, flame-retardant, self-extinguishing, and highly resistant to oils, greases, coolants, and lubricants.

The float switch works reliably with all liquids with a density of 0.7 g/cm³ or higher. Depending on the installation position, it can be operated as a normally open (NO) or normally closed (NC) contact – simply by turning the float. This step is not necessary for versions with an integrated changeover contact, as both functions are already integrated.

For reliable operation, we recommend the optionally available mounting bracket (item no. 300787). The mounting bracket ensures the float switch is positioned as vertically as possible, with a maximum deviation of 30°, so the float can slide freely on the shaft without jamming or jamming.

🔌 Connection to the following water detectors required (please order separately):

SHT 5000, SHT 5001 or level controller SHT 5001 from Elektrotechnik Schabus.

Cabling via thin, unshielded LiYY control cable (2 × 0.14 mm²) – max. 50 m cable length per scanner.

📏 Cable extension up to 50 meters possible

The factory-installed cable length can be extended up to 50 m. The recommended cross-section is 2 × 0.14 mm².

⚠️ Notes on cable routing and area of application

The LIYY cables used are only temporarily waterproof and, according to the manufacturer, are flame-retardant, low-adhesion, and self-extinguishing. They are resistant to oils, greases, coolants, and lubricants, but are not suitable for permanent water contact.

⚠️ Safety notice:

The LIYY cables must never be laid parallel to 230 V mains cables to avoid interference and safety risks.

IMPORTANT SAFETY NOTICE:

An incorrect electrical connection can destroy the sensitive reed contacts and thus cause a malfunction – in the worst case, resulting in personal injury or property damage.

Please therefore note:

No direct connection to inductive loads (e.g. relays, solenoid valves)

No direct connection to capacitive loads (e.g. PLC/PCS – see our “active” water sensors and float switches) or long cables > 50 m

Permissible switching capacity must not be exceeded

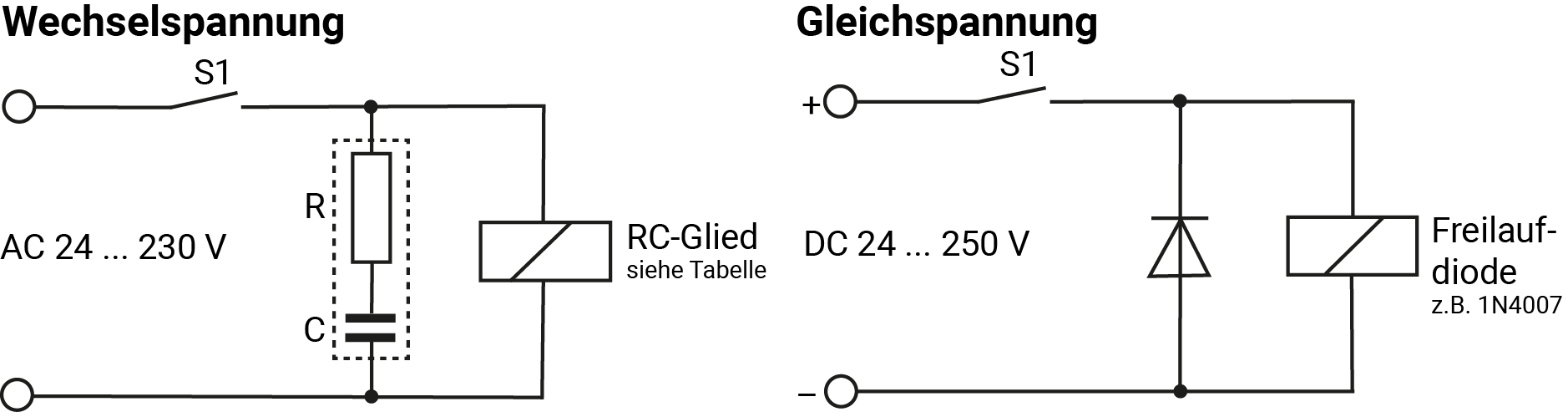

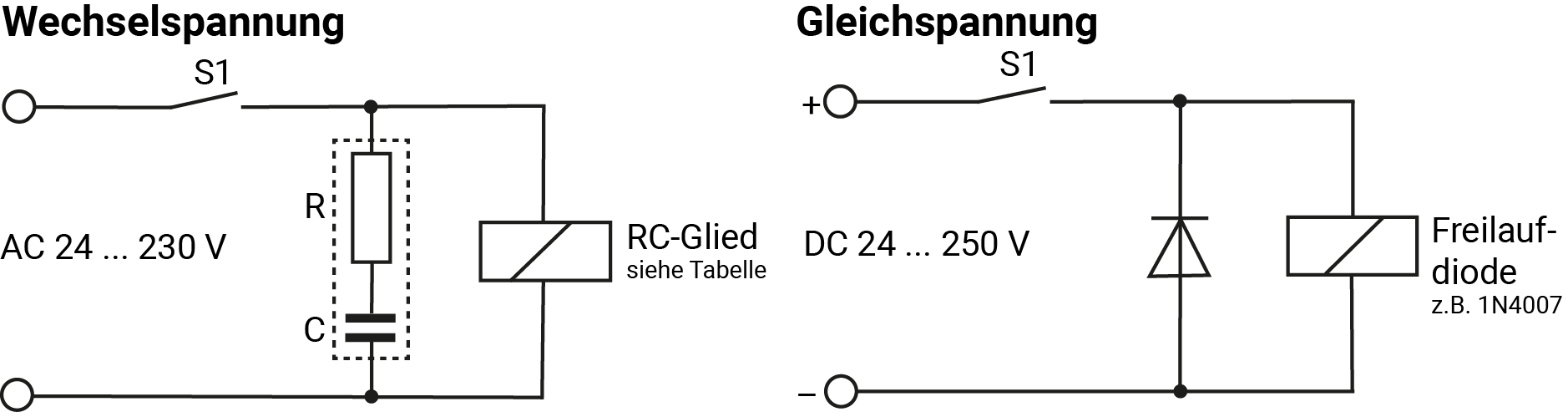

👉 For inductive loads, protection by means of an RC element or freewheeling diode is mandatory.

.

| RC elements for reed contacts 10 ... 40 VA | |||

| Tension | Resistance | capacity | RC element type |

| AC 24 V | 100 Ω | 0.33 μF | A3/24 |

| Operating voltage | max. 25 V AC/60 V DC/0.5 A |

|---|---|

| Switching performance | max. 10 watts |

| Protection class | IP68 |

| Dimensions(WxWxD) | |

| Relay contact | Opener, closer |

| Line | 2.5m | 2×0.14mm2 | white |

| Material | Connection thread V4A stainless steel, shaft turned and milled from solid V4A stainless steel, shaft V4A stainless steel, Ø 8.3mm, 62.8mm long |

| Medium | min. 0.7g/cm³ density, unpressurized |

| Assembly | Installation position vertical, max. ±30° inclination, mounting angle |

The compact mini float switches made of V4A stainless steel are ideal for applications with particularly aggressive or chlorinated liquids – for example, in chlorinated pool water, salt water, or weak chemical alkalis. Compared to V2A, V4A offers even greater corrosion resistance thanks to the addition of molybdenum and titanium. This makes the float switch suitable for use in environments where V2A reaches its limits.

The shaft of the float switch is milled and turned from solid V4A stainless steel, making it extremely stable – even under constant stress. The float body is made of thin, also rust-proof V4A sheet metal. Inside, a high-quality reed contact from Meder, which is watertightly cast into the shaft and firmly soldered, ensures permanently reliable signal transmission.

Combined with low switching power – less than 5 volts and 1 milliampere – the float switch achieves a service life of up to one trillion switching cycles. This means no mechanical wear, no maintenance, and no failures. Once installed, the switch operates precisely and reliably over the long term – even in confined spaces.

The float switch is equipped as standard with a 2.5-meter-long LiYY/PVC cable. According to the manufacturer, this cable is temporarily waterproof, flame-retardant, self-extinguishing, and highly resistant to oils, greases, coolants, and lubricants.

The float switch works reliably with all liquids with a density of 0.7 g/cm³ or higher. Depending on the installation position, it can be operated as a normally open (NO) or normally closed (NC) contact – simply by turning the float. This step is not necessary for versions with an integrated changeover contact, as both functions are already integrated.

For reliable operation, we recommend the optionally available mounting bracket (item no. 300787). The mounting bracket ensures the float switch is positioned as vertically as possible, with a maximum deviation of 30°, so the float can slide freely on the shaft without jamming or jamming.

🔌 Connection to the following water detectors required (please order separately):

SHT 5000, SHT 5001 or level controller SHT 5001 from Elektrotechnik Schabus.

Cabling via thin, unshielded LiYY control cable (2 × 0.14 mm²) – max. 50 m cable length per scanner.

📏 Cable extension up to 50 meters possible

The factory-installed cable length can be extended up to 50 m. The recommended cross-section is 2 × 0.14 mm².

⚠️ Notes on cable routing and area of application

The LIYY cables used are only temporarily waterproof and, according to the manufacturer, are flame-retardant, low-adhesion, and self-extinguishing. They are resistant to oils, greases, coolants, and lubricants, but are not suitable for permanent water contact.

⚠️ Safety notice:

The LIYY cables must never be laid parallel to 230 V mains cables to avoid interference and safety risks.

IMPORTANT SAFETY NOTICE:

An incorrect electrical connection can destroy the sensitive reed contacts and thus cause a malfunction – in the worst case, resulting in personal injury or property damage.

Please therefore note:

No direct connection to inductive loads (e.g. relays, solenoid valves)

No direct connection to capacitive loads (e.g. PLC/PCS – see our “active” water sensors and float switches) or long cables > 50 m

Permissible switching capacity must not be exceeded

👉 For inductive loads, protection by means of an RC element or freewheeling diode is mandatory.

.

| RC elements for reed contacts 10 ... 40 VA | |||

| Tension | Resistance | capacity | RC element type |

| AC 24 V | 100 Ω | 0.33 μF | A3/24 |

| Operating voltage | max. 25 V AC/60 V DC/0.5 A |

|---|---|

| Switching performance | max. 10 watts |

| Protection class | IP68 |

| Dimensions(WxWxD) | |

| Relay contact | Opener, closer |

| Line | 2.5m | 2×0.14mm2 | white |

| Material | Connection thread V4A stainless steel, shaft turned and milled from solid V4A stainless steel, shaft V4A stainless steel, Ø 8.3mm, 62.8mm long |

| Medium | min. 0.7g/cm³ density, unpressurized |

| Assembly | Installation position vertical, max. ±30° inclination, mounting angle |