Do you have an account?

Log in, so that checkout is faster.

Availability for pickups could not be loaded

Item number: 200941

Delivery time: 2-3 working days

View full details

Scope of delivery

<ul>

<li>Mini float switch – V2A stainless steel</li>

<li>cast on 2.5 meters of LIYY control cable 2 x 0.14 mm²</li>

<li>Operating Instructions Water Sensors | Float Switches | Accessories</li>

</ul>

<h2 data-start="217" data-end="269"></h2>

<h2 data-start="217" data-end="269">🧪 Robust stainless steel for demanding media</h2>

<p data-start="270" data-end="773">The compact <strong data-start="284" data-end="327">mini float switches made of V2A stainless steel</strong> are ideal for applications with increased requirements – such as in <strong data-start="396" data-end="424">food processing</strong>, where hygiene and material durability are top priorities. Compared to plastic variants, stainless steel offers a particularly smooth, hygienic surface on which bacteria are significantly less likely to settle. V2A is also resistant to weak acids and alkalis – a clear advantage when used with aggressive media.</p>

<hr data-start="775" data-end="778" />

<h2 data-start="780" data-end="821">⚙️ Durable thanks to precise manufacturing</h2>

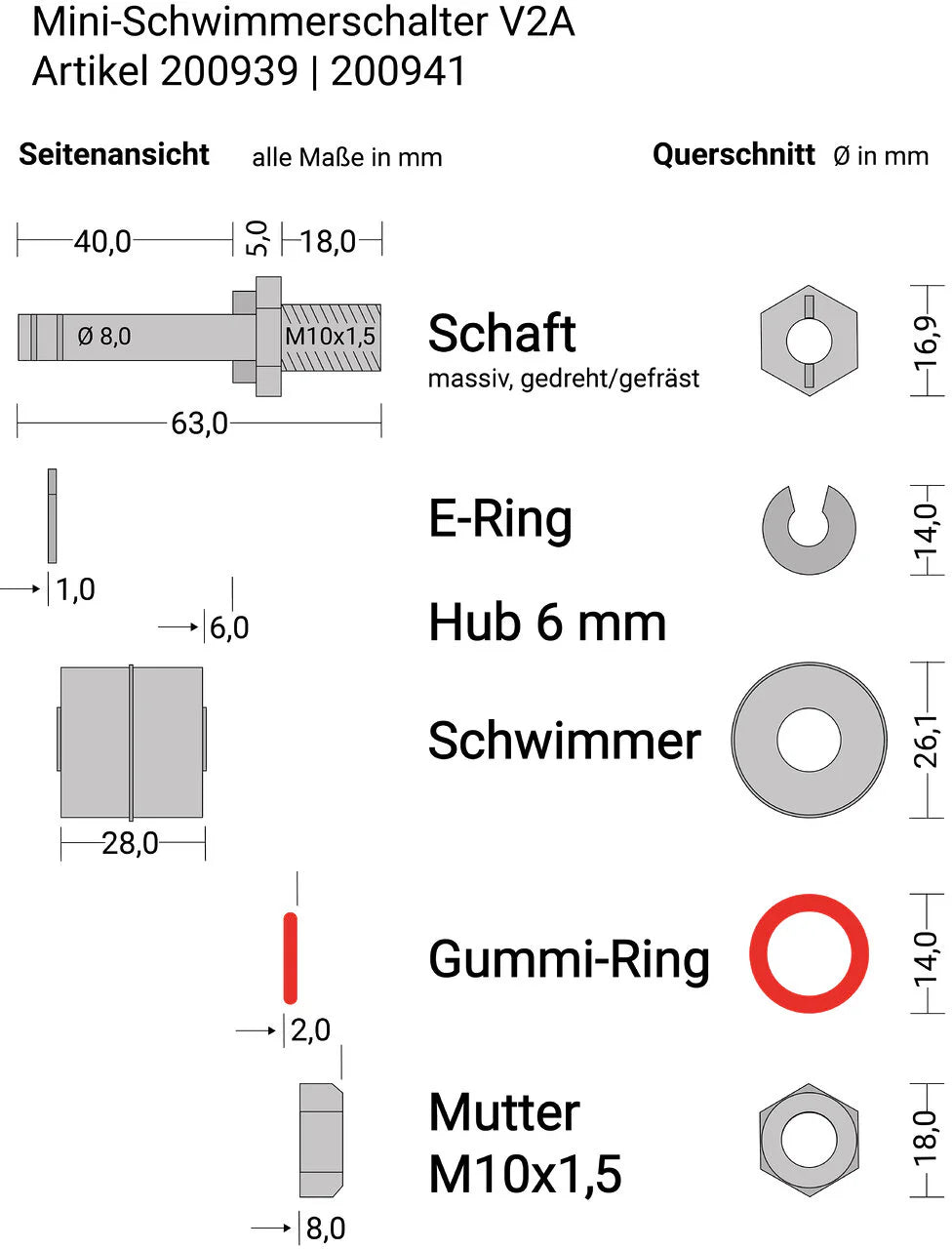

<p data-start="822" data-end="1233">The shaft of the float switch is milled and turned from solid V2A stainless steel, making it extremely stable – even under constant stress. The float body is made of thin, rust-proof stainless steel sheet. Inside, a high-quality reed contact from Meder, which is waterproof and firmly soldered into the shaft, ensures permanently reliable signal transmission.</p>

<hr data-start="1235" data-end="1238" />

<h2 data-start="1240" data-end="1279">🔁 Extremely durable & maintenance-free</h2>

<p data-start="1280" data-end="1638">Combined with low switching power – under 5 volts and 1 milliampere – the float switch achieves a service life of up to a <strong data-start="1425" data-end="1449">trillion switching cycles</strong>. This means no mechanical wear, no maintenance, and no failures. Once installed, the switch operates precisely and reliably over the long term – even in confined spaces.</p>

<hr data-start="1640" data-end="1643" />

<h2 data-start="1645" data-end="1703">🔌 Connection cable included</h2>

<p data-start="1704" data-end="2105">The float switch is equipped as standard with a <strong data-start="1754" data-end="1789">2.5-meter-long LiYY/PVC cable.</strong> According to the manufacturer, this cable is <strong data-start="1831" data-end="1856">temporarily waterproof, <strong data-start="1858" data-end="1873">flame-retardant, <strong data-start="1875" data-end="1896">self-extinguishing, and highly resistant to oils, greases, coolants, and lubricants.</p>

<hr data-start="2107" data-end="2110" />

<h2 data-start="2112" data-end="2161">🌊 Suitable for a wide variety of liquids</h2>

<p data-start="2162" data-end="2524">The float switch functions reliably with all liquids with a <strong data-start="2243" data-end="2266">density of 0.7 g/cm³ or higher. Depending on the installation position, it can be operated as a <strong data-start="2305" data-end="2323">normally open (NO)</strong> or <strong data-start="2329" data-end="2344">normally closed (NC)</strong> – simply by turning the float body. This step is not necessary for versions with an integrated changeover contact, as both functions are already integrated.</p>

<hr data-start="2526" data-end="2529" />

<h2 data-start="2531" data-end="2567">🧩 Installation with suitable accessories</h2>

<p data-start="2568" data-end="2959">For reliable operation, we recommend the optionally available <strong data-start="2639" data-end="2674">mounting bracket (item no. 300787). </strong>The mounting bracket ensures the float switch is positioned as vertically as possible, with a maximum deviation of 30° – so that the float can slide freely on the shaft without jamming or jamming.</p>

<p data-start="2568" data-end="2959"></p>

<div>

<h2 data-start="1736" data-end="1773">⚙️ Technical Note & Connection</h2>

<p data-start="1775" data-end="2009">🔌 <strong data-start="1778" data-end="1829">Connection to the following water detectors required (please order separately)</strong><br data-start="1830" data-end="1833" /><strong><a href="https://www.elektrotechnik-schabus.de/warnsysteme-wasser/wassermelder-sht-5000">SHT 5000</a></strong> or <strong><a href="https://www.elektrotechnik-schabus.de/warnsysteme-wasser/wassermelder-sht-5001">SHT 5001</a></strong> from Elektrotechnik Schabus.<br data-start="1893" data-end="1896" />Cabling via thin, unshielded <strong data-start="1933" data-end="1970"><a href="https://www.elektrotechnik-schabus.de/anlaufstrombegrenzer-kabel/steuerleitung-liyy">LiYY control cable</a> (2 × 0.14 mm²)</strong> – max. 50 m cable length per scanner.</p>

</div>

<div>

<p data-start="937" data-end="1104"><strong data-start="937" data-end="982">📏 Cable extension up to 50 meters possible</strong><br data-start="982" data-end="985" />The factory-set cable length can be extended up to <strong data-start="1024" data-end="1043">50 m</strong>. The recommended cross-section is <strong data-start="1087" data-end="1103">2 × 0.14 mm²</strong>.</p>

<hr data-start="1106" data-end="1109" />

<p data-start="1111" data-end="1440"><strong data-start="1111" data-end="1162">⚠️ Notes on cable routing and application area</strong><br data-start="1162" data-end="1165" />The <strong data-start="1181" data-end="1195">LIYY cables used are only <strong data-start="1205" data-end="1230">temporarily waterproof</strong> and, according to the manufacturer, are <strong data-start="1251" data-end="1302">flame-retardant, low-adhesion, and self-extinguishing</strong>. They are resistant to <strong data-start="1340" data-end="1382">oils, greases, coolants, and lubricants</strong>, but not suitable for permanent contact with water.</p>

<p data-start="1111" data-end="1440"><strong data-start="82" data-end="108">⚠️ Safety note:</strong> LIYY cables must <strong data-start="135" data-end="178">never be laid parallel to 230 V power lines</strong> to avoid interference and safety risks.</p>

</div>

<h3 data-start="1528" data-end="1587">⚠️ What do I need to consider when connecting the electrical system?</h3>

<p data-start="1588" data-end="1819"><strong data-start="1588" data-end="1621">IMPORTANT SAFETY NOTICE:</strong><br data-start="1621" data-end="1624" />An <strong data-start="1628" data-end="1663">incorrect electrical connection</strong> can destroy the sensitive <strong data-start="1687" data-end="1713">reed contacts</strong> and thereby cause a malfunction – in the worst case, resulting in personal injury or property damage.</p>

<p data-start="1821" data-end="1850">Please note:</p>

<ul data-start="1851" data-end="2092">

<li data-start="1851" data-end="1932">

<p data-start="1853" data-end="1932">No direct connection to <strong data-start="1880" data-end="1900">inductive loads</strong> (e.g. relays, solenoid valves)</p>

</li>

<li data-start="1933" data-end="2029">

<p data-start="1935" data-end="2029">No direct connection to <strong data-start="1962" data-end="1983">capacitive loads</strong> (e.g. PLC/PCS – see our <a href="https://www.elektrotechnik-schabus.de/warnsysteme-wasser">"active" water sensors and float switches)</a> or long cables > 50 m</p>

</li>

<li data-start="2030" data-end="2092">

<p data-start="2032" data-end="2092"><strong data-start="2032" data-end="2092">Permissible switching capacity must not be exceeded</strong></p>

</li>

</ul>

<p data-start="2094" data-end="2200">👉 <strong data-start="2097" data-end="2122">For inductive loads, protection using an <strong data-start="2146" data-end="2177">RC element or freewheeling diode</strong> is mandatory.</p>

<img class="alignleft wp-image-21806 " src="https://www.elektrotechnik-schabus.de/wp-content/uploads/2023/01/Anschlussplan-Schwimmerschalter.jpg" alt="" width="704" height="187" />

<table width="491">

<body>

<tr>

<td colspan="4" width="353">RC elements for reed contacts 10 ... 40 VA</td>

</tr>

<tr>

<td>Voltage</td>

<td>Resistance</td>

<td>Capacity</td>

<td>RC element type</td>

</tr>

<tr>

<td>AC 24 V</td>

<td>100 Ω</td>

<td>0.33 μF</td>

<td>A 3/24</td>

</tr>

</tbody>

</table>

<div id="text_product_description">

</div>

WEEE NO.: DE91394868

<div id="es_performance_features_list"></div>

| Operating voltage | max. 25 V AC/60 V DC/0.5 A |

|---|---|

| Switching performance | max. 10 watts |

| Functional area | -20°C/max. +100°C |

| Protection class | IP 68, cable only waterproof for a short time |

| Dimensions(WxWxD) | |

| Weight | 0.10kg |

| Line | 2.5m | 2×0.14mm2 | white |

| Material | Connection thread V2A stainless steel, shaft turned and milled from solid V2A, shaft V2A stainless steel, ⌀ 8.3mm, 62.8mm long |

| Medium | min. 0.7g/cm³ density, unpressurized |

Scope of delivery

<ul>

<li>Mini float switch – V2A stainless steel</li>

<li>cast on 2.5 meters of LIYY control cable 2 x 0.14 mm²</li>

<li>Operating Instructions Water Sensors | Float Switches | Accessories</li>

</ul>

<h2 data-start="217" data-end="269"></h2>

<h2 data-start="217" data-end="269">🧪 Robust stainless steel for demanding media</h2>

<p data-start="270" data-end="773">The compact <strong data-start="284" data-end="327">mini float switches made of V2A stainless steel</strong> are ideal for applications with increased requirements – such as in <strong data-start="396" data-end="424">food processing</strong>, where hygiene and material durability are top priorities. Compared to plastic variants, stainless steel offers a particularly smooth, hygienic surface on which bacteria are significantly less likely to settle. V2A is also resistant to weak acids and alkalis – a clear advantage when used with aggressive media.</p>

<hr data-start="775" data-end="778" />

<h2 data-start="780" data-end="821">⚙️ Durable thanks to precise manufacturing</h2>

<p data-start="822" data-end="1233">The shaft of the float switch is milled and turned from solid V2A stainless steel, making it extremely stable – even under constant stress. The float body is made of thin, rust-proof stainless steel sheet. Inside, a high-quality reed contact from Meder, which is waterproof and firmly soldered into the shaft, ensures permanently reliable signal transmission.</p>

<hr data-start="1235" data-end="1238" />

<h2 data-start="1240" data-end="1279">🔁 Extremely durable & maintenance-free</h2>

<p data-start="1280" data-end="1638">Combined with low switching power – under 5 volts and 1 milliampere – the float switch achieves a service life of up to a <strong data-start="1425" data-end="1449">trillion switching cycles</strong>. This means no mechanical wear, no maintenance, and no failures. Once installed, the switch operates precisely and reliably over the long term – even in confined spaces.</p>

<hr data-start="1640" data-end="1643" />

<h2 data-start="1645" data-end="1703">🔌 Connection cable included</h2>

<p data-start="1704" data-end="2105">The float switch is equipped as standard with a <strong data-start="1754" data-end="1789">2.5-meter-long LiYY/PVC cable.</strong> According to the manufacturer, this cable is <strong data-start="1831" data-end="1856">temporarily waterproof, <strong data-start="1858" data-end="1873">flame-retardant, <strong data-start="1875" data-end="1896">self-extinguishing, and highly resistant to oils, greases, coolants, and lubricants.</p>

<hr data-start="2107" data-end="2110" />

<h2 data-start="2112" data-end="2161">🌊 Suitable for a wide variety of liquids</h2>

<p data-start="2162" data-end="2524">The float switch functions reliably with all liquids with a <strong data-start="2243" data-end="2266">density of 0.7 g/cm³ or higher. Depending on the installation position, it can be operated as a <strong data-start="2305" data-end="2323">normally open (NO)</strong> or <strong data-start="2329" data-end="2344">normally closed (NC)</strong> – simply by turning the float body. This step is not necessary for versions with an integrated changeover contact, as both functions are already integrated.</p>

<hr data-start="2526" data-end="2529" />

<h2 data-start="2531" data-end="2567">🧩 Installation with suitable accessories</h2>

<p data-start="2568" data-end="2959">For reliable operation, we recommend the optionally available <strong data-start="2639" data-end="2674">mounting bracket (item no. 300787). </strong>The mounting bracket ensures the float switch is positioned as vertically as possible, with a maximum deviation of 30° – so that the float can slide freely on the shaft without jamming or jamming.</p>

<p data-start="2568" data-end="2959"></p>

<div>

<h2 data-start="1736" data-end="1773">⚙️ Technical Note & Connection</h2>

<p data-start="1775" data-end="2009">🔌 <strong data-start="1778" data-end="1829">Connection to the following water detectors required (please order separately)</strong><br data-start="1830" data-end="1833" /><strong><a href="https://www.elektrotechnik-schabus.de/warnsysteme-wasser/wassermelder-sht-5000">SHT 5000</a></strong> or <strong><a href="https://www.elektrotechnik-schabus.de/warnsysteme-wasser/wassermelder-sht-5001">SHT 5001</a></strong> from Elektrotechnik Schabus.<br data-start="1893" data-end="1896" />Cabling via thin, unshielded <strong data-start="1933" data-end="1970"><a href="https://www.elektrotechnik-schabus.de/anlaufstrombegrenzer-kabel/steuerleitung-liyy">LiYY control cable</a> (2 × 0.14 mm²)</strong> – max. 50 m cable length per scanner.</p>

</div>

<div>

<p data-start="937" data-end="1104"><strong data-start="937" data-end="982">📏 Cable extension up to 50 meters possible</strong><br data-start="982" data-end="985" />The factory-set cable length can be extended up to <strong data-start="1024" data-end="1043">50 m</strong>. The recommended cross-section is <strong data-start="1087" data-end="1103">2 × 0.14 mm²</strong>.</p>

<hr data-start="1106" data-end="1109" />

<p data-start="1111" data-end="1440"><strong data-start="1111" data-end="1162">⚠️ Notes on cable routing and application area</strong><br data-start="1162" data-end="1165" />The <strong data-start="1181" data-end="1195">LIYY cables used are only <strong data-start="1205" data-end="1230">temporarily waterproof</strong> and, according to the manufacturer, are <strong data-start="1251" data-end="1302">flame-retardant, low-adhesion, and self-extinguishing</strong>. They are resistant to <strong data-start="1340" data-end="1382">oils, greases, coolants, and lubricants</strong>, but not suitable for permanent contact with water.</p>

<p data-start="1111" data-end="1440"><strong data-start="82" data-end="108">⚠️ Safety note:</strong> LIYY cables must <strong data-start="135" data-end="178">never be laid parallel to 230 V power lines</strong> to avoid interference and safety risks.</p>

</div>

<h3 data-start="1528" data-end="1587">⚠️ What do I need to consider when connecting the electrical system?</h3>

<p data-start="1588" data-end="1819"><strong data-start="1588" data-end="1621">IMPORTANT SAFETY NOTICE:</strong><br data-start="1621" data-end="1624" />An <strong data-start="1628" data-end="1663">incorrect electrical connection</strong> can destroy the sensitive <strong data-start="1687" data-end="1713">reed contacts</strong> and thereby cause a malfunction – in the worst case, resulting in personal injury or property damage.</p>

<p data-start="1821" data-end="1850">Please note:</p>

<ul data-start="1851" data-end="2092">

<li data-start="1851" data-end="1932">

<p data-start="1853" data-end="1932">No direct connection to <strong data-start="1880" data-end="1900">inductive loads</strong> (e.g. relays, solenoid valves)</p>

</li>

<li data-start="1933" data-end="2029">

<p data-start="1935" data-end="2029">No direct connection to <strong data-start="1962" data-end="1983">capacitive loads</strong> (e.g. PLC/PCS – see our <a href="https://www.elektrotechnik-schabus.de/warnsysteme-wasser">"active" water sensors and float switches)</a> or long cables > 50 m</p>

</li>

<li data-start="2030" data-end="2092">

<p data-start="2032" data-end="2092"><strong data-start="2032" data-end="2092">Permissible switching capacity must not be exceeded</strong></p>

</li>

</ul>

<p data-start="2094" data-end="2200">👉 <strong data-start="2097" data-end="2122">For inductive loads, protection using an <strong data-start="2146" data-end="2177">RC element or freewheeling diode</strong> is mandatory.</p>

<img class="alignleft wp-image-21806 " src="https://www.elektrotechnik-schabus.de/wp-content/uploads/2023/01/Anschlussplan-Schwimmerschalter.jpg" alt="" width="704" height="187" />

<table width="491">

<body>

<tr>

<td colspan="4" width="353">RC elements for reed contacts 10 ... 40 VA</td>

</tr>

<tr>

<td>Voltage</td>

<td>Resistance</td>

<td>Capacity</td>

<td>RC element type</td>

</tr>

<tr>

<td>AC 24 V</td>

<td>100 Ω</td>

<td>0.33 μF</td>

<td>A 3/24</td>

</tr>

</tbody>

</table>

<div id="text_product_description">

</div>

WEEE NO.: DE91394868

<div id="es_performance_features_list"></div>

| Operating voltage | max. 25 V AC/60 V DC/0.5 A |

|---|---|

| Switching performance | max. 10 watts |

| Functional area | -20°C/max. +100°C |

| Protection class | IP 68, cable only waterproof for a short time |

| Dimensions(WxWxD) | |

| Weight | 0.10kg |

| Line | 2.5m | 2×0.14mm2 | white |

| Material | Connection thread V2A stainless steel, shaft turned and milled from solid V2A, shaft V2A stainless steel, ⌀ 8.3mm, 62.8mm long |

| Medium | min. 0.7g/cm³ density, unpressurized |