Do you have an account?

Log in, so that checkout is faster.

Availability for pickups could not be loaded

Item number: 201760

Delivery time: 2-3 working days

View full details

Scope of delivery

The 150 mm diameter electric supply air damper ensures an airtight connection in accordance with DIN 1946 Part 4 thanks to its high-quality EPDM seal . It is TÜV-tested and designed for pressures up to 1000 Pa – ideal for use in ventilation systems, exhaust air systems, or in combination with Schabus controls.

A powerful, high-torque capacitor motor opens and closes the flap slowly (approximately 150 seconds) to reliably press the seal against the galvanized steel pipe. This extends the service life and increases airtightness. Control is via mains voltage via a 3-wire connection cable (3 × 0.75 mm²). When the end stop is reached, the motor shuts off automatically – for safe, low-maintenance operation.

The supply air damper can be controlled, for example, via theSchabus KZS 200 electrical supply air control , a simple light switch , or a self-resetting push button directly on the motor . During manual operation, the transmission is automatically disengaged as long as the button is pressed.

The installed EPDM seal is resistant to aging and can withstand mildly aggressive vapors and chemicals – ideal for long-lasting, reliable ventilation solutions.

WEEE NO.: DE91394868

| Operating voltage | 100-240 volts AC/50-60 Hz |

|---|---|

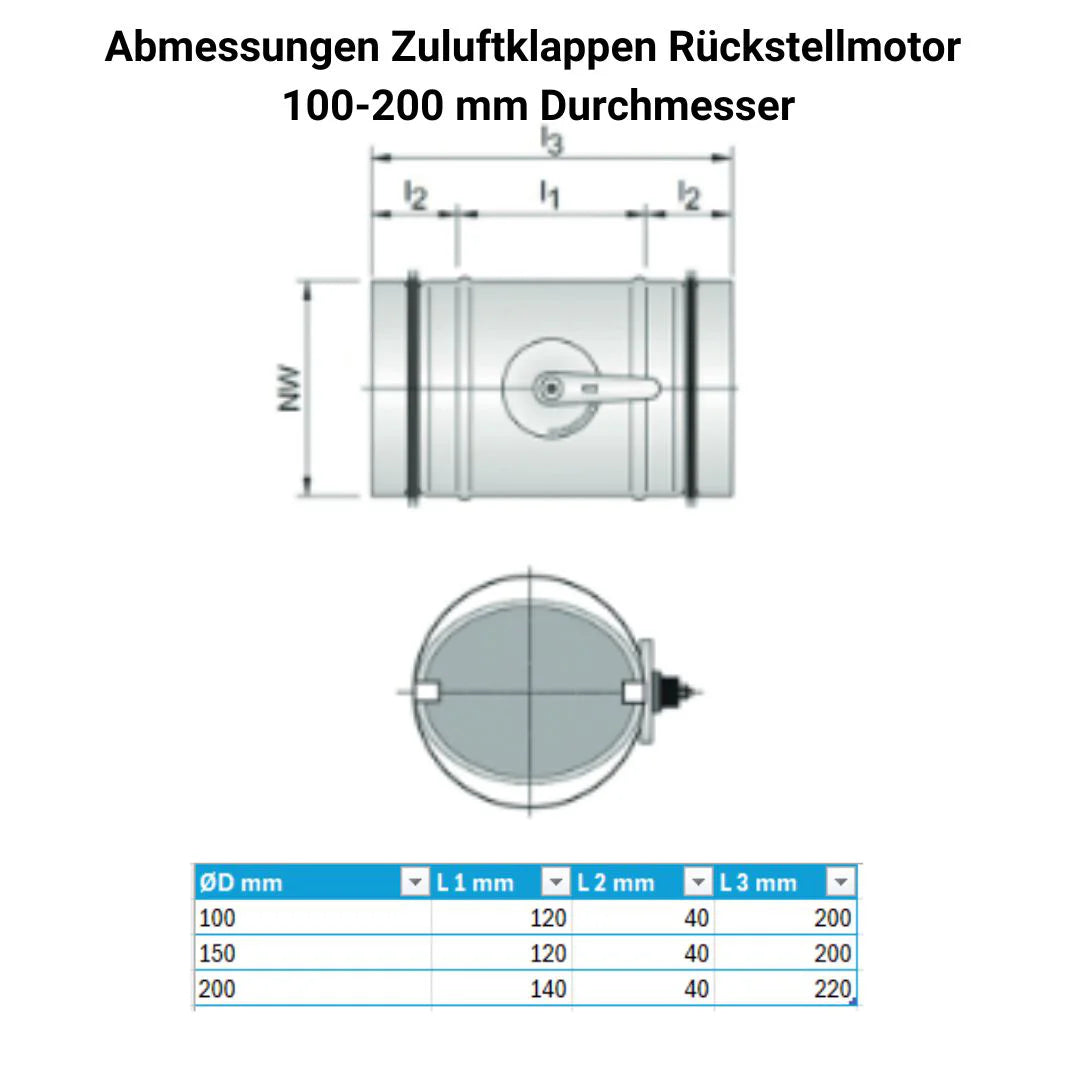

| Dimensions(WxWxD) | |

| Power consumption | 1.5W, 3.5VA |

| Brand | Belimo |

| Pressure | max. 1000 Pa |

| Line | 1 meter, 3×0.75 mm² |

| Protection class | IP54 |

| Temperature | 0°C – max. +60°C |

| Time | approx. 150 seconds closing/opening time |

Scope of delivery

The 150 mm diameter electric supply air damper ensures an airtight connection in accordance with DIN 1946 Part 4 thanks to its high-quality EPDM seal . It is TÜV-tested and designed for pressures up to 1000 Pa – ideal for use in ventilation systems, exhaust air systems, or in combination with Schabus controls.

A powerful, high-torque capacitor motor opens and closes the flap slowly (approximately 150 seconds) to reliably press the seal against the galvanized steel pipe. This extends the service life and increases airtightness. Control is via mains voltage via a 3-wire connection cable (3 × 0.75 mm²). When the end stop is reached, the motor shuts off automatically – for safe, low-maintenance operation.

The supply air damper can be controlled, for example, via theSchabus KZS 200 electrical supply air control , a simple light switch , or a self-resetting push button directly on the motor . During manual operation, the transmission is automatically disengaged as long as the button is pressed.

The installed EPDM seal is resistant to aging and can withstand mildly aggressive vapors and chemicals – ideal for long-lasting, reliable ventilation solutions.

WEEE NO.: DE91394868

| Operating voltage | 100-240 volts AC/50-60 Hz |

|---|---|

| Dimensions(WxWxD) | |

| Power consumption | 1.5W, 3.5VA |

| Brand | Belimo |

| Pressure | max. 1000 Pa |

| Line | 1 meter, 3×0.75 mm² |

| Protection class | IP54 |

| Temperature | 0°C – max. +60°C |

| Time | approx. 150 seconds closing/opening time |