Do you have an account?

Log in, so that checkout is faster.

Availability for pickups could not be loaded

Item number: 201749

Delivery time: 2-3 working days

View full details

The ATW 519 reliably detects whether a fireplace, solid fuel boiler, or heating appliance is in operation – and makes this information available to other control systems. Especially in so-called bivalent heating mode , where, for example, a solid fuel boiler is operated in addition to an oil or gas heating system, the temperature monitor offers an important safety function: It prevents both systems from operating simultaneously. It can also be used to safely shut down exhaust air systems if an open fire is burning in the room – to prevent dangerous negative pressure and the backflow of flue gases.

Bivalent heating mode : For example, locks the gas heating when the wood stove is running

Safe ventilation : Prevents cooker hoods or exhaust fans from operating when there is an open flame

Heating control : Uses the measured exhaust gas temperature, e.g. to switch on a storage charging pump

Fuel boiler burnout : safer thanks to the integrated control lamp

The ATW 519 flue gas temperature monitor is TÜV-tested according to DIN EN 14597 and approved for continuous use in heat-generating systems. The contact closes at a flue gas temperature of approximately 40 °C, thus providing a clear signal: the furnace is active. In practice, it switches on other components or transmits the status to ventilation or heating controls.

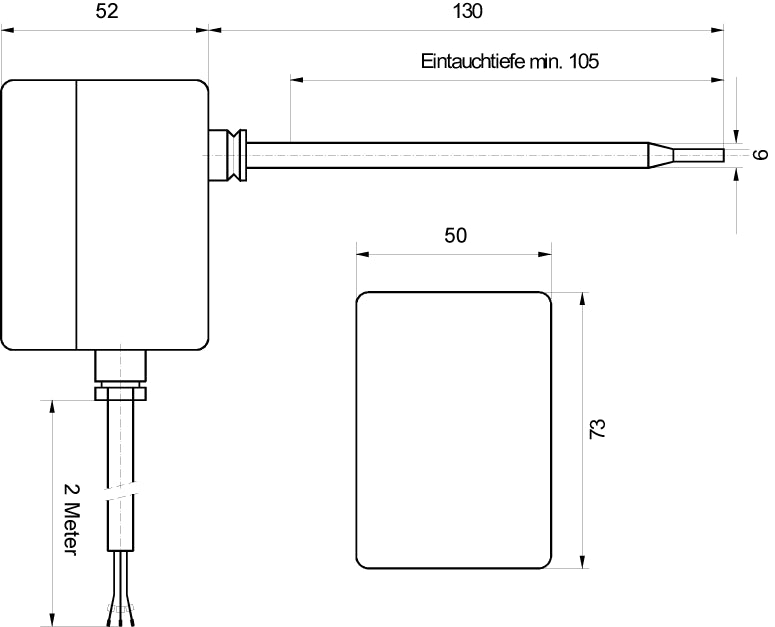

The robust design is maintenance-free and designed for high temperatures: The stainless steel sensor can withstand temperatures up to 500 °C , and the switch head and the pre-assembled 2 m long, temperature-resistant silicone cable can withstand temperatures up to 180 °C. The cable can be extended as required with a 2-wire cable outside of the hot area.

The sensor is attached directly to the flue pipe using the mounting flange, ideally at least 80 cm from the top edge of the stove . This distance ensures that the sensor measures a meaningful temperature—neither too hot nor too slow. Installation is straightforward, and its operation is consistently reliable.

Note: When installing the sensor, make sure that it is not bent or damaged.

WEEE No.: 91394868

| Switching performance | 16 (4) A 400 V, at cos <0 1 (0.6) |

|---|---|

| Protection class | IP67 |

| TÜV tested | TÜV-tested |

| Brand | Cetrotec |

| Area of application | Exhaust air systems, incineration site |

| Limit range | 0-400 °C factory set and sealed |

| Line | 2 m (4-wire) | Silicone | max. 180°C |

| Medium | Air or flue gas |

| Switching difference | approx. 15 K |

| Switching accuracy | +/- 7 K |

| Switching point | 40° C, factory set |

| Temperature | 0-500 °C medium temperature, max. 180 °C ambient temperature |

| Time | < 45 seconds response time |

The ATW 519 reliably detects whether a fireplace, solid fuel boiler, or heating appliance is in operation – and makes this information available to other control systems. Especially in so-called bivalent heating mode , where, for example, a solid fuel boiler is operated in addition to an oil or gas heating system, the temperature monitor offers an important safety function: It prevents both systems from operating simultaneously. It can also be used to safely shut down exhaust air systems if an open fire is burning in the room – to prevent dangerous negative pressure and the backflow of flue gases.

Bivalent heating mode : For example, locks the gas heating when the wood stove is running

Safe ventilation : Prevents cooker hoods or exhaust fans from operating when there is an open flame

Heating control : Uses the measured exhaust gas temperature, e.g. to switch on a storage charging pump

Fuel boiler burnout : safer thanks to the integrated control lamp

The ATW 519 flue gas temperature monitor is TÜV-tested according to DIN EN 14597 and approved for continuous use in heat-generating systems. The contact closes at a flue gas temperature of approximately 40 °C, thus providing a clear signal: the furnace is active. In practice, it switches on other components or transmits the status to ventilation or heating controls.

The robust design is maintenance-free and designed for high temperatures: The stainless steel sensor can withstand temperatures up to 500 °C , and the switch head and the pre-assembled 2 m long, temperature-resistant silicone cable can withstand temperatures up to 180 °C. The cable can be extended as required with a 2-wire cable outside of the hot area.

The sensor is attached directly to the flue pipe using the mounting flange, ideally at least 80 cm from the top edge of the stove . This distance ensures that the sensor measures a meaningful temperature—neither too hot nor too slow. Installation is straightforward, and its operation is consistently reliable.

Note: When installing the sensor, make sure that it is not bent or damaged.

WEEE No.: 91394868

| Switching performance | 16 (4) A 400 V, at cos <0 1 (0.6) |

|---|---|

| Protection class | IP67 |

| TÜV tested | TÜV-tested |

| Brand | Cetrotec |

| Area of application | Exhaust air systems, incineration site |

| Limit range | 0-400 °C factory set and sealed |

| Line | 2 m (4-wire) | Silicone | max. 180°C |

| Medium | Air or flue gas |

| Switching difference | approx. 15 K |

| Switching accuracy | +/- 7 K |

| Switching point | 40° C, factory set |

| Temperature | 0-500 °C medium temperature, max. 180 °C ambient temperature |

| Time | < 45 seconds response time |