Do you have an account?

Log in, so that checkout is faster.

Availability for pickups could not be loaded

Item number: 21006

Delivery time: 2-3 working days

View full details

Scope of delivery

Airflow monitor - solenoid shut-off valve (gas)

This control unit ensures the mutual interlocking of an exhaust system (extractor hood) and the gas supply for the oven and gas cooktops in the catering industry. The gas supply to the oven is only released when the exhaust system is switched on. This is controlled by the airflow monitor in the exhaust system.

The airflow monitor is placed in the exhaust air stream of a range hood behind the grease filter and monitors whether the exhaust air is actually flowing at the required and adjustable speed. If this is the case, a potential-free changeover relay is activated, which releases the gas supply for commercial gas cooktops via a gas solenoid shut-off valve. The airflow monitor is the basis for the so-called "mutual interlocking of exhaust air and gas supply."

The key switch is only intended to ensure that the gas supply can be turned on in the event of a faulty airflow monitor, to prevent economic damage to the restaurant. This may only be done in exceptional cases and under supervised supervision; the ventilation system must be running!

The flow monitor operates according to the calorimetric principle and monitors air flows for excess or undershoot of a previously set threshold. With the calorimetric measuring principle, a temperature-sensitive resistor is heated. The heating process is carried out by a separate heating resistor. A flow in the medium dissipates heat from the measuring resistor, changing the temperature of the resistor and thus its resistance. This change is evaluated. However, not only the velocity of the flowing medium but also its temperature influences the amount of heat dissipated, therefore a relationship must be established between flow and temperature. This is done using a second temperature-dependent measuring resistor near the first. The second measuring resistor (temperature compensation) is not heated and is used for temperature measurement.

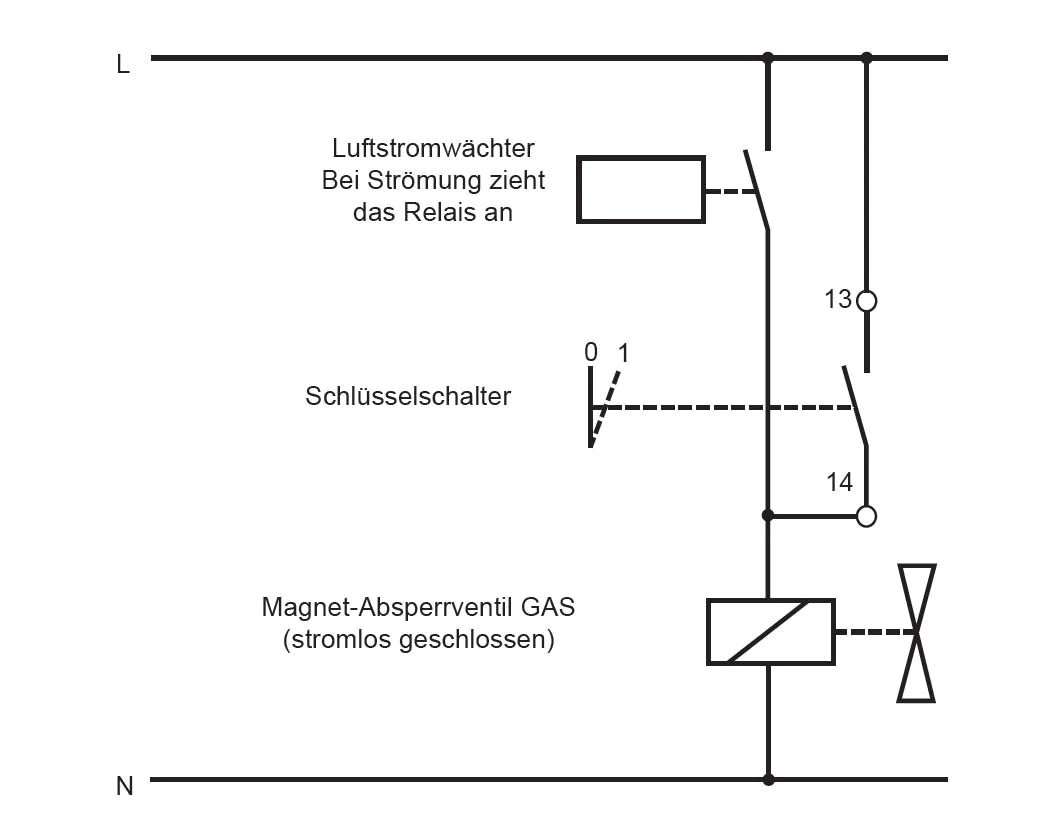

Air flow monitor – solenoid shut-off valve (gas) – key switch

This control unit ensures the mutual interlocking of an exhaust system and the gas supply for the oven in a catering establishment. The gas supply to the oven is only released when the exhaust system is switched on. This is controlled by the airflow monitor in the exhaust system. The key switch only serves to ensure that the gas supply can still be switched on in the event of a fault in the airflow monitor, thus preventing financial damage to the catering establishment.

This may only be done in exceptional circumstances and under supervised supervision. The ventilation system must be running!

Connection example

WEEE NO.: DE91394868

| Operating voltage | 230 V AC / 50-60 Hz |

|---|---|

| Switching performance | 3500 VA (2300 W), 16 A (10 A) |

| Functional area | -20°C / +60°C |

| Protection class | IP54 |

| TÜV tested | TÜV-tested |

| Dimensions(WxWxD) | |

| Power consumption | 4 VA max |

| Measuring range | 0.1-30 m/s |

| Control voltage | 18 V |

Scope of delivery

Airflow monitor - solenoid shut-off valve (gas)

This control unit ensures the mutual interlocking of an exhaust system (extractor hood) and the gas supply for the oven and gas cooktops in the catering industry. The gas supply to the oven is only released when the exhaust system is switched on. This is controlled by the airflow monitor in the exhaust system.

The airflow monitor is placed in the exhaust air stream of a range hood behind the grease filter and monitors whether the exhaust air is actually flowing at the required and adjustable speed. If this is the case, a potential-free changeover relay is activated, which releases the gas supply for commercial gas cooktops via a gas solenoid shut-off valve. The airflow monitor is the basis for the so-called "mutual interlocking of exhaust air and gas supply."

The key switch is only intended to ensure that the gas supply can be turned on in the event of a faulty airflow monitor, to prevent economic damage to the restaurant. This may only be done in exceptional cases and under supervised supervision; the ventilation system must be running!

The flow monitor operates according to the calorimetric principle and monitors air flows for excess or undershoot of a previously set threshold. With the calorimetric measuring principle, a temperature-sensitive resistor is heated. The heating process is carried out by a separate heating resistor. A flow in the medium dissipates heat from the measuring resistor, changing the temperature of the resistor and thus its resistance. This change is evaluated. However, not only the velocity of the flowing medium but also its temperature influences the amount of heat dissipated, therefore a relationship must be established between flow and temperature. This is done using a second temperature-dependent measuring resistor near the first. The second measuring resistor (temperature compensation) is not heated and is used for temperature measurement.

Air flow monitor – solenoid shut-off valve (gas) – key switch

This control unit ensures the mutual interlocking of an exhaust system and the gas supply for the oven in a catering establishment. The gas supply to the oven is only released when the exhaust system is switched on. This is controlled by the airflow monitor in the exhaust system. The key switch only serves to ensure that the gas supply can still be switched on in the event of a fault in the airflow monitor, thus preventing financial damage to the catering establishment.

This may only be done in exceptional circumstances and under supervised supervision. The ventilation system must be running!

Connection example

WEEE NO.: DE91394868

| Operating voltage | 230 V AC / 50-60 Hz |

|---|---|

| Switching performance | 3500 VA (2300 W), 16 A (10 A) |

| Functional area | -20°C / +60°C |

| Protection class | IP54 |

| TÜV tested | TÜV-tested |

| Dimensions(WxWxD) | |

| Power consumption | 4 VA max |

| Measuring range | 0.1-30 m/s |

| Control voltage | 18 V |