Couldn't load pickup availability

SKU: 200884

Delivery time: 2-3 working days

View full details

Features

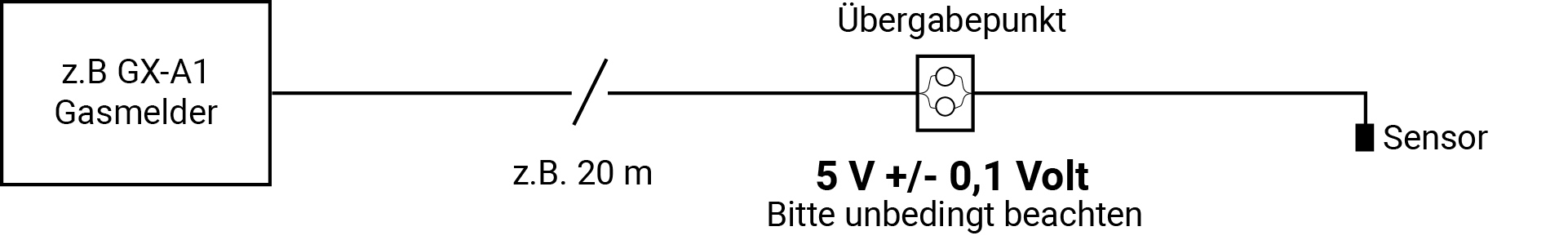

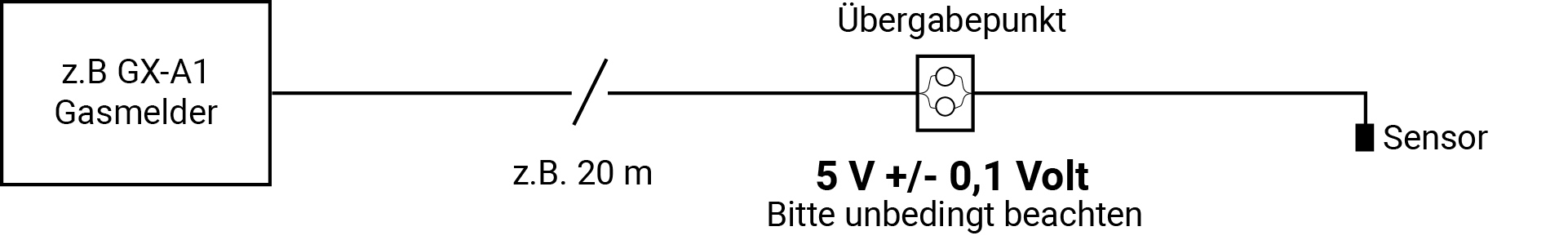

| Operating voltage: | 5 V |

| Sensor type: | NDIR - Infrared |

| Trigger concentration: | Pre-alarm 2000 ppm, main alarm 2500 ppm |

| Humidity (ambient): | 5-90% RH (non-condensing) |

| Functional area: | -10 °C / +50 °C |

| Storage temperature: | -20 °C / +70 °C |

| Life: | approx. >5 years |

| Protection class: | IP20 |

| Cable length: | 2.5 m |

| Cable Ø: | 3.5 mm |

| Dimensions (HxWxD): | 52x27x29 mm |

Description of the functionality for those interested in technology

An NDIR sensor is a non-dispersive infrared sensor consisting of an IR diode as the light source, an optical wavelength filter, and an IR detector. The ambient air diffuses through a membrane into a chamber. Each gas has its own wavelength in the infrared spectrum at which it optimally absorbs light. The amount is measured electro-optically and thus provides a reference for the existing concentration.

The optical filter ensures that only the narrow spectrum of interest is evaluated. A pure air mixture is enclosed in a second chamber. The same measurement is then performed alternately in both chambers at a low pulse frequency of just under 1 Hz.

External influences such as temperatures affect both chambers and are thus largely compensated, since only the difference between the two chambers is evaluated. A powerful

The microcontroller system first converts the low detector currents into a voltage, which is then converted into digital signals by an AD converter. This is where an initial filtering process takes place, which checks the signals for plausibility and eliminates strong, rapid, possibly unusual signal changes.

smoothed and replaced with intermediate values. The read voltage values are then related to a concentration expressible in ppm according to an internal reference and output as a pulse-width modulated continuous signal. Using an analog low-pass filter, the pulses are converted back into a modulated DC voltage, achieving approximately 1 mV per ppm.

Fresh air contains approximately 400 ppm CO2, so the sensor should output approximately 0.4 volts in fresh air, which is roughly what the display shows on the GX-A1 warning device. Since the GX-A1 specifically features an additional signal filter to smooth the signal and prevent false alarms, readings of 0.2–0.6 volts are possible. All gas warning devices from Elektrotechnik Schabus are actually warning devices, not measuring devices; therefore, such a deviation is acceptable and does not constitute a fault. The values are displayed to identify trends and to determine whether, for example, ventilation measures are achieving the desired effect.

ES gas detectors activate the pre-alarm at 2 volts, if provided for in the device, and the main alarm at 2.5 volts. Any relays that may be present also activate at this point, and built-in piezoelectric sensors emit loud audible warnings. These thresholds correspond to approximately 2000 and 2500 ppm. These values are well below the limits at which they become dangerous to humans. For example, the maximum workplace concentration (MAK) in Germany for an exposure of at least 8 hours is 5000 ppm CO2. Thus, a detector with the GX-DS sensor is an early warning system.

Description of the functionality for those interested in technology

An NDIR sensor is a non-dispersive infrared sensor consisting of an IR diode as the light source, an optical wavelength filter, and an IR detector. The ambient air diffuses through a membrane into a chamber. Each gas has its own wavelength in the infrared spectrum at which it optimally absorbs light. The amount is measured electro-optically and thus provides a reference for the existing concentration.

The optical filter ensures that only the narrow spectrum of interest is evaluated. A pure air mixture is enclosed in a second chamber. The same measurement is then performed alternately in both chambers at a low pulse frequency of just under 1 Hz.

External influences such as temperatures affect both chambers and are thus largely compensated, since only the difference between the two chambers is evaluated. A powerful

The microcontroller system first converts the low detector currents into a voltage, which is then converted into digital signals by an AD converter. This is where an initial filtering process takes place, which checks the signals for plausibility and eliminates strong, rapid, possibly unusual signal changes.

smoothed and replaced with intermediate values. The read voltage values are then related to a concentration expressible in ppm according to an internal reference and output as a pulse-width modulated continuous signal. Using an analog low-pass filter, the pulses are converted back into a modulated DC voltage, achieving approximately 1 mV per ppm.

Fresh air contains approximately 400 ppm CO2, so the sensor should output approximately 0.4 volts in fresh air, which is roughly what the display shows on the GX-A1 warning device. Since the GX-A1 specifically features an additional signal filter to smooth the signal and prevent false alarms, readings of 0.2–0.6 volts are possible. All gas warning devices from Elektrotechnik Schabus are actually warning devices, not measuring devices; therefore, such a deviation is acceptable and does not constitute a fault. The values are displayed to identify trends and to determine whether, for example, ventilation measures are achieving the desired effect.

ES gas detectors activate the pre-alarm at 2 volts, if provided for in the device, and the main alarm at 2.5 volts. Any relays that may be present also activate at this point, and built-in piezoelectric sensors emit loud audible warnings. These thresholds correspond to approximately 2000 and 2500 ppm. These values are well below the limits at which they become dangerous to humans. For example, the maximum workplace concentration (MAK) in Germany for an exposure of at least 8 hours is 5000 ppm CO2. Thus, a detector with the GX-DS sensor is an early warning system.

| Operating voltage | 5 V = stabilized, max. 170 mA |

|---|---|

| Functional area | -10°C / +50°C |

| Protection class | IP20 |

| Weight | 0.07 kg |

| life | 6 – max. 10 years (depending on environmental conditions), approx. 5 years |

| Line | 2.5 m | 3×0.75mm2 |

| humidity | 10% – 90% rH, non-condensing |

| Trigger concentration | > 2000 ppm CO2 pre-alarm, > 2500 ppm CO2 main alarm |

| sensor | external, NDIR infrared |

| temperature | -20°C / +70°C storage temperature |

Features

| Operating voltage: | 5 V |

| Sensor type: | NDIR - Infrared |

| Trigger concentration: | Pre-alarm 2000 ppm, main alarm 2500 ppm |

| Humidity (ambient): | 5-90% RH (non-condensing) |

| Functional area: | -10 °C / +50 °C |

| Storage temperature: | -20 °C / +70 °C |

| Life: | approx. >5 years |

| Protection class: | IP20 |

| Cable length: | 2.5 m |

| Cable Ø: | 3.5 mm |

| Dimensions (HxWxD): | 52x27x29 mm |

Description of the functionality for those interested in technology

An NDIR sensor is a non-dispersive infrared sensor consisting of an IR diode as the light source, an optical wavelength filter, and an IR detector. The ambient air diffuses through a membrane into a chamber. Each gas has its own wavelength in the infrared spectrum at which it optimally absorbs light. The amount is measured electro-optically and thus provides a reference for the existing concentration.

The optical filter ensures that only the narrow spectrum of interest is evaluated. A pure air mixture is enclosed in a second chamber. The same measurement is then performed alternately in both chambers at a low pulse frequency of just under 1 Hz.

External influences such as temperatures affect both chambers and are thus largely compensated, since only the difference between the two chambers is evaluated. A powerful

The microcontroller system first converts the low detector currents into a voltage, which is then converted into digital signals by an AD converter. This is where an initial filtering process takes place, which checks the signals for plausibility and eliminates strong, rapid, possibly unusual signal changes.

smoothed and replaced with intermediate values. The read voltage values are then related to a concentration expressible in ppm according to an internal reference and output as a pulse-width modulated continuous signal. Using an analog low-pass filter, the pulses are converted back into a modulated DC voltage, achieving approximately 1 mV per ppm.

Fresh air contains approximately 400 ppm CO2, so the sensor should output approximately 0.4 volts in fresh air, which is roughly what the display shows on the GX-A1 warning device. Since the GX-A1 specifically features an additional signal filter to smooth the signal and prevent false alarms, readings of 0.2–0.6 volts are possible. All gas warning devices from Elektrotechnik Schabus are actually warning devices, not measuring devices; therefore, such a deviation is acceptable and does not constitute a fault. The values are displayed to identify trends and to determine whether, for example, ventilation measures are achieving the desired effect.

ES gas detectors activate the pre-alarm at 2 volts, if provided for in the device, and the main alarm at 2.5 volts. Any relays that may be present also activate at this point, and built-in piezoelectric sensors emit loud audible warnings. These thresholds correspond to approximately 2000 and 2500 ppm. These values are well below the limits at which they become dangerous to humans. For example, the maximum workplace concentration (MAK) in Germany for an exposure of at least 8 hours is 5000 ppm CO2. Thus, a detector with the GX-DS sensor is an early warning system.

Description of the functionality for those interested in technology

An NDIR sensor is a non-dispersive infrared sensor consisting of an IR diode as the light source, an optical wavelength filter, and an IR detector. The ambient air diffuses through a membrane into a chamber. Each gas has its own wavelength in the infrared spectrum at which it optimally absorbs light. The amount is measured electro-optically and thus provides a reference for the existing concentration.

The optical filter ensures that only the narrow spectrum of interest is evaluated. A pure air mixture is enclosed in a second chamber. The same measurement is then performed alternately in both chambers at a low pulse frequency of just under 1 Hz.

External influences such as temperatures affect both chambers and are thus largely compensated, since only the difference between the two chambers is evaluated. A powerful

The microcontroller system first converts the low detector currents into a voltage, which is then converted into digital signals by an AD converter. This is where an initial filtering process takes place, which checks the signals for plausibility and eliminates strong, rapid, possibly unusual signal changes.

smoothed and replaced with intermediate values. The read voltage values are then related to a concentration expressible in ppm according to an internal reference and output as a pulse-width modulated continuous signal. Using an analog low-pass filter, the pulses are converted back into a modulated DC voltage, achieving approximately 1 mV per ppm.

Fresh air contains approximately 400 ppm CO2, so the sensor should output approximately 0.4 volts in fresh air, which is roughly what the display shows on the GX-A1 warning device. Since the GX-A1 specifically features an additional signal filter to smooth the signal and prevent false alarms, readings of 0.2–0.6 volts are possible. All gas warning devices from Elektrotechnik Schabus are actually warning devices, not measuring devices; therefore, such a deviation is acceptable and does not constitute a fault. The values are displayed to identify trends and to determine whether, for example, ventilation measures are achieving the desired effect.

ES gas detectors activate the pre-alarm at 2 volts, if provided for in the device, and the main alarm at 2.5 volts. Any relays that may be present also activate at this point, and built-in piezoelectric sensors emit loud audible warnings. These thresholds correspond to approximately 2000 and 2500 ppm. These values are well below the limits at which they become dangerous to humans. For example, the maximum workplace concentration (MAK) in Germany for an exposure of at least 8 hours is 5000 ppm CO2. Thus, a detector with the GX-DS sensor is an early warning system.

| Operating voltage | 5 V = stabilized, max. 170 mA |

|---|---|

| Functional area | -10°C / +50°C |

| Protection class | IP20 |

| Weight | 0.07 kg |

| life | 6 – max. 10 years (depending on environmental conditions), approx. 5 years |

| Line | 2.5 m | 3×0.75mm2 |

| humidity | 10% – 90% rH, non-condensing |

| Trigger concentration | > 2000 ppm CO2 pre-alarm, > 2500 ppm CO2 main alarm |

| sensor | external, NDIR infrared |

| temperature | -20°C / +70°C storage temperature |