🛰️ How functions a NDIR sensor?

Technology for Interested parties – the CO₂ measurement with Infrared

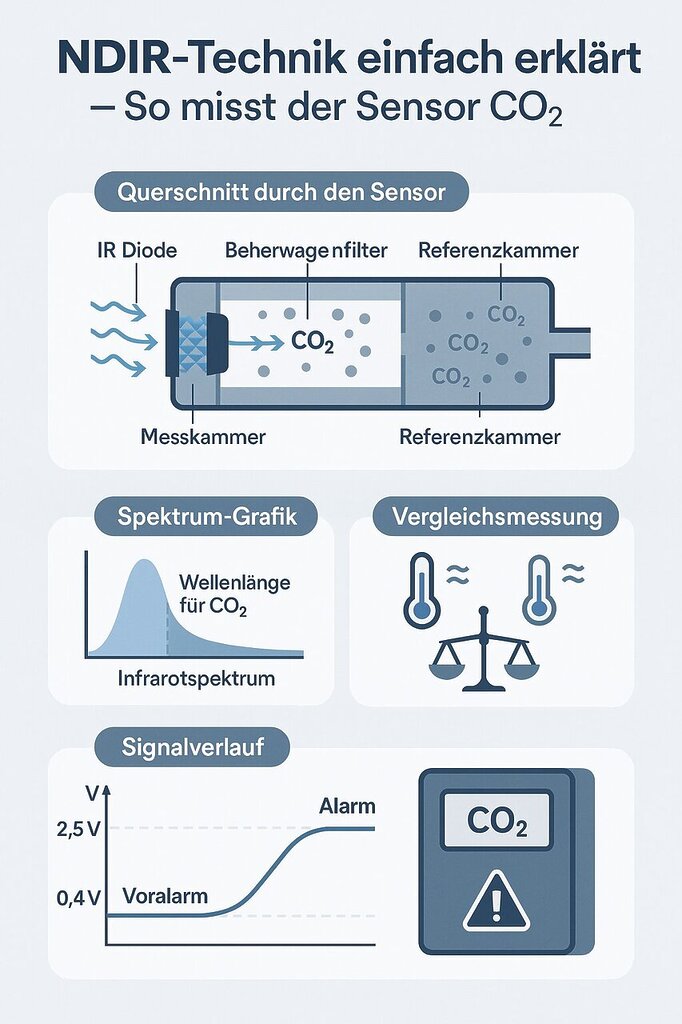

A NDIR sensor

(non-dispersive infrared sensor) is a precise and reliable technology for measuring gases such as CO₂. It is frequently used in gas detectors from Elektrotechnik Schabus and operates on the principle of infrared light absorption.

🔧 Construction and function one NDIR sensors

The sensor consists out of three essential Components:

The ambient air passes through a membrane into a measuring chamber. There, the infrared light hits the gas molecules. Each gas absorbs light in a very specific range of the infrared spectrum. The filter only allows the wavelength relevant to the target gas to pass through—in the case of the CO₂ sensor, this is the typical absorption range for carbon dioxide.

How an NDIR sensor measures CO₂: This infographic clearly explains the structure, signal processing, and alarm functions of a modern infrared gas sensor—as used in gas detectors from Elektrotechnik Schabus. (AI-generated)

⚖️ Comparative measurement for higher accuracy

A second reference volume, filled with pure air , is used for comparison. The infrared measurement is performed alternately in both chambers – with a pulse frequency of approximately 1 Hz. This largely compensates for external influences such as temperature fluctuations , as the difference between the two measured values is evaluated.

📈 Signal processing and output

A microcontroller converts the minimum detector currents into voltage and then into digital signals. An internal algorithm checks the signal quality , filters out interference, and smooths out strong fluctuations.

The result: A CO₂ concentration in ppm (parts per million) , which is output as a pulse-width modulated continuous signal . After analog smoothing with a low-pass filter, the result is, for example:

🔔 Advertisement and Alarm in the Device GX- A1

In the GX-A1 gas detector from Elektrotechnik Schabus, this signal is displayed on the screen. Due to an additional filter to prevent false alarms, the value can fluctuate between 0.2 and 0.6 volts – corresponding to 200 to 600 ppm CO₂.

At certain thresholds, the device automatically triggers an alarm:

These values are well below the limits that pose a health risk – the MAK (maximum workplace concentration) for CO₂, for example, is 5000 ppm for an 8-hour exposure.

✅ Conclusion: early warning system instead of Laboratory measurement

Gas detectors from Elektrotechnik Schabus are not precise measuring devices, but reliable early warning systems that indicate CO₂ concentrations and provide timely warnings before health risks arise.